Abstract

Rapid developments in proton-exchange membrane (PEM) fuel cell technology suggest that small-scale fuel cell systems may soon make inroads in both automotive and residential power conversion applications. PEM fuel cell systems offer clean and efficient production of electricity, and the capital costs of these systems are expected to decline rapidly as production expands. The deregulation of regional electric utilities is enabling new regimes of distributed power generation, to which fuel cell systems are ideally suited. Also, fuel cell systems are presently the focus of intense research efforts among industrial, academic, and government organizations, but this work is primarily concentrated on technical hurdles to fuel cell commercialization. Also needed are research efforts that examine the theoretical cost and benefit relationships, and environmental impacts of fuel cell systems as used in different settings. This includes innovative ways of introducing fuel cell systems into transportation and stationary power system markets, and novel policies to make fuel cell systems attractive at the early stages of commercialization.

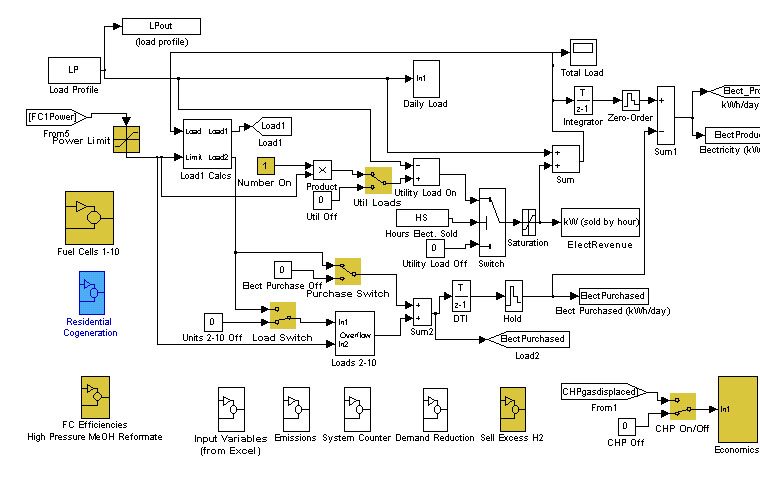

This project is modeling and analyzing the economics of small-scale (5-250 kW) PEM fuel cell systems used for distributed electricity generation, and assessing the full fuel-cycle emissions of greenhouse gases and criteria pollutants from different fuel and end-use technology combinations, using a MATLAB/Simulink-based building electrical load and fuel cell response model. This model, known as CETEEM, includes an assessment of fuel cell system performance in terms of overall system efficiency, modeled as a function of the percentage of peak load that the fuel cell meets during any model hour in a simulation run, as well as the cost of electricity produced and approximate in-basin and out-of-basin emssions of criteria pollutants and greenhouse gases.

We have thus far used CETEEM to conduct two investigations:

- a comparison of the costs of producing electricity from stationary PEM fuel cells and fuel cell vehicles (FCVs) used for distributed power generation; and

- an analysis of hydrogen energy stations (or "H2-E Stations") that co-produce electricity and pure hydrogen using the same natural gas reformer; electricity with a building-integrated stationary fuel cell, and hydrogen to refuel FCVs as an "offshoot" using available reformer capacity.

The findings from both of these analyses suggest that there are interesting synergies between stationary and mobile applications of PEM fuel cell technology, and that both the use of FCVs to generate power and the concept of the "H2-E Station" appear to be worthy of continued study and analysis. Some details of the findings from these studies can be found below, and full details can be found in the reports in the publications section of this website.

PEM fuel cells are being considered for a range of applications, from portable power generation,

to distributed generation of power in the 5-250 kW range, to use in a new generation of fuel cell

powered electric vehicles. While much analysis is considering each of these applications in turn,

there are also many interesting ways in which the use of fuel cells in one sector of the economy

might complement uses in another sector. Or, they may simply be very novel ways in which fuel

cells might be used, perhaps in multiple ways by a single system owner/operator.

For example, the impending electrification of a fraction of the light-duty vehicle fleet has led

some analysts to suggest that the electricity stored in batteries or generated with fuel cells could

be used to provide peak power, or even base-load power, to the electrical grid (Kempton and

Letendre, 1997; Kissock, 1998; Lovins and Williams, 1999). The current motor vehicle fleet in

the U.S. (about 146 million vehicles) has a total shaft power generating capacity of about 14 TW,

which if connected to generators could produce about 12 TW of electric power (Kempton and

Letendre, 1997). This is approximately sixteen times the present stationary electric generating

capacity in the U.S.! Motor vehicles are driven on average about one hour a day, so the

generating capacity of the vehicle fleet is idle approximately 95% of the time.

In California, a fleet of 100,000 fuel cell EVs connected in this vehicle-to-grid (or "V2G")

fashion could produce about 3.8 GW of power for the grid, assuming 40 kW net fuel cell output

power per vehicle and 95% vehicle availability. Even if the vehicles were only available as

generating capacity 50% of the time, about 2 GW of generating capacity could be provided by

each 100,000 vehicles. If, for example, 50% of today's vehicle population in San Diego alone

were fuel cell vehicles by 2025, each capable of supplying 50 kW of power to the grid 50% of

the time, the total generating capacity of these vehicles would be over 35% of the present level of

installed generating capacity in the entire state of California. A key feature of this concept is that

the automotive and light-truck fuel cell capacity will automatically be distributed to the locations

where people are working by virtue of the vehicles also being used for transportation. This

literally places the power by the people, paving the way for efficiency through increased

distributed power management.

Use of fuel cell EVs in this way could help to reduce the need to add generating capacity to meet

the expected 1.8% per year growth in electricity demand (and 1.7% per year growth in peak

power demand) for California over the next decade (Goeke, et al., 1998), and the forecast

electricity supply deficit of 2.8 GW in 2003 and 6.7 GW in 2007 (CEC, 1997). Power capacity

for current electric utilities has been purchased at a cost of about $1,000/kW, with costs of about

$300/kW for modern natural gas systems (Kempton and Letendre, 1997). Current PEM fuel cell

system costs are on the order of $10,000 per kW for automotive systems and at least $2,500 per

kW for small stationary systems (compared with costs of about $4,000 per kW for 200-kW

stationary phosphoric acid fuel cell systems), but costs for vehicle applications are projected to

rapidly decline to much lower levels as production expands - perhaps even as low as $50/kW in

mass production (Lomax, et al., 1997).

Residential and commercial fuel cell systems could also be used in the same manner to provide

distributed generating capacity, thereby delaying or eliminating the need to build new centralized

electricity generating plants. Companies such as Plug Power, L.L.C. are currently developing

small PEM fuel cell systems for residential applications. While introduction of these systems (in

conjunction with General Electric) has been delayed relative to initial expectations, these ~7 kW

systems are expected to sell for $7,500-10,000 when first introduced, with costs declining over

time to potentially less than $4,000. The average electric load for a house is about 2 kW, so

some of the time excess electricity generated by these systems could be sold back to the grid at

rates of perhaps 2-5 kW per household. In order to facilitate additions of power to the grid from

DG sources at times when the grid needs peak power, net-metering policies could be designed to

allow such power additions at particular times, for example from 1 PM to 8 PM only.

Furthermore, there are many interesting and novel applications of fuel cell technology that we

are exploring now and that can be further explored, such as the "H2-E Stations" that we are

investigating that co-produce electricity and hydrogen to refuel FCVs using a common fuel

reformer. Finally, in addition to PEM fuel cells, there are several

other fuel cell types of interest to DG, and a host of other technologies such as microturbines,

photovoltaics, wind turbines, other reciprocating engines, battery and other storage systems and

peak power devices, etc. We plan to methodically expand CETEEM to include these additional

technologies in the coming years.

In order to analyze the economics of operating stationary and motor vehicle PEM fuel cell

systems to provide power to buildings and/or the electrical grid, we have constructed an

integrated MATLAB/Simulink/Excel model. This model, which we have named the Clean

Energy Technology Economic and Emissions Model (or CETEEM, pronounced "see team"), has

been designed in order to assess the economics and emissions of criteria pollutants and

greenhouse gases (GHGs) associated with the use of CETs for distributed power generation.

CETEEM has thus far been developed around the scenario of the use of PEM fuel cell systems

powered by hydrogen produced with natural gas reformers, but it can be readily modified to

characterize other CETs and fueling arrangements. These might include solar PV systems, wind

power generating systems, other fuel cell technologies such as solid-oxide fuel cells, fuel cell

systems operating in conjunction with electrolyzers to produce hydrogen (and hybrid

renewable/fuel cell systems), natural gas powered microturbines, and other DG technologies.

CETEEM has the following principal features:

Over the past two years, we have been addressing the following specific research questions:

In addressing these questions, we are integrating advances in fuel cell system performance

modeling, geographic research methods, and technology price and performance forecasting

(Lipman and Sperling, 1997; Duke and Kammen, 1999), to analyze the potential costs and

benefits of the operation of small PEM fuel cell systems, and to propose, test, and evaluate state

and federal policy options to potentially support this distributed clean energy resource. The

study is also considering uncertainties and sensitivities of key input variables, opportunities for

policy action to encourage fuel cell system proliferation, and examining the potential impacts on

utilities and consumers of candidate policies to facilitate fuel cell system deployment.

Sample Results from Stationary PEM FC vs. PEM FCV Used for DG

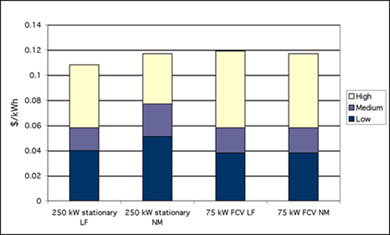

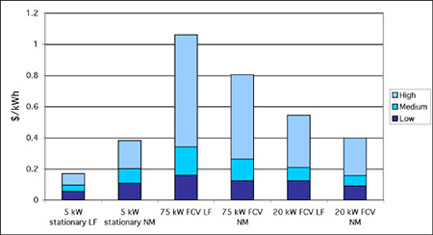

While the costs of producing power from stationary and motor vehicle systems are rather

different in terms of the costs involved - for stationary systems much of the cost is capital cost

while for FCVs much of the cost is for periodically refurbishing the vehicle's fuel cell stack - the

economics of producing power from these systems can be comparable, and potentially

competitive with grid power in the future, if the systems are operated with similar overall

efficiencies. However, results are highly sensitive to the compounding effects of variations in

key input variables, as shown in the figures below. Where FCVs are used to produce power to

meet very low load levels, such as at individual residences (e.g. and operate at very high

turndown ratios), their efficiencies suffer and they become much less economically attractive at

producing power. This suggests that net-metering policies may be critical to improving the

economics of FCVs used to produce power in this way.

Sample Results from Hydrogen Energy Station Economic Analysis

One interesting option for developing hydrogen-refueling infrastructure for early FCVs is

the concept of the "hydrogen energy station" (or 'H2E-Station'). These H2E-Stations

would be either dedicated refueling facilities, or a key component of the energy

production, use, and management portion of a commercial or industrial facility. The

energy station component would consist of a natural gas reformer or other hydrogen

generating appliance, a stationary fuel cell integrated into the building with the potential

capability for combined heat and power (CHP) production, and a hydrogen compression,

storage, and dispensing facility.

In essence, H2E-Stations would seek to capture synergies between producing hydrogen

for a stationary fuel cell electricity generator that provides part or all of the power for the

local building load (as well as the capability to supply excess electricity to the grid), and

refueling FCVs with additional high-purity hydrogen that is produced through the same

hydrogen-generation system. In principle, many different H2E-Station concepts and

designs are possible, including:

In addition, FCVs parked near the H2E-Station for any sizable length of time could in

principle supply electricity to the building or grid, since they would have access to a fuel

supply (as in the above example).

Our analysis of the economics of several potential H2E-Station designs shows that for

the California setting examined, H2E-Stations appear to be potentially attractive ways of

supplying small numbers of FCVs with hydrogen (download full report from link below).

In general, H2E-Stations tend to be more attractive economically than dedicated hydrogen

refueling stations, especially for low numbers of vehicles supported per day, but the

economics depend importantly on several variables including natural gas and electricity

prices, captial equipment costs, the hydrogen sales price, and fuel cell maintenance and

stack refurbishment costs.

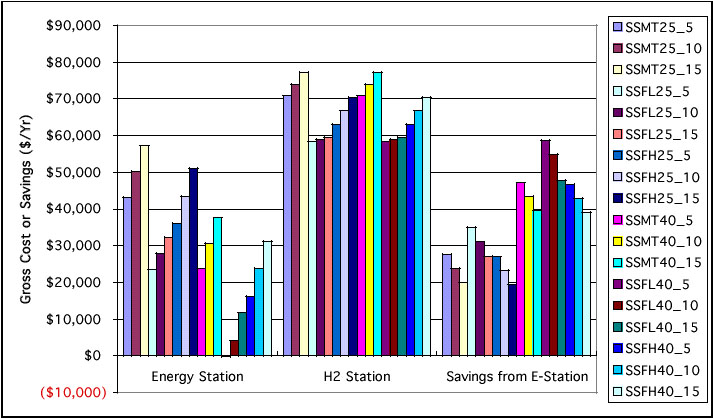

The first figure, below, shows that for all of the service station cases examined the H2E-Station designs are more attractive economically than dedicated hydrogen refueling

stations. None of the dedicated or H2E-Stations are economically profitable with so few

vehicles supported, but the H2E-Stations offer a lower-cost pathway to ultimately

supporting greater numbers of vehicles profitably.

Note: FL = future low cost case; FH future high cost case; MT = medium term case; SS = service

station; X_Y = Fuel Cell Size in kW_# of FCVs per Day refueled.

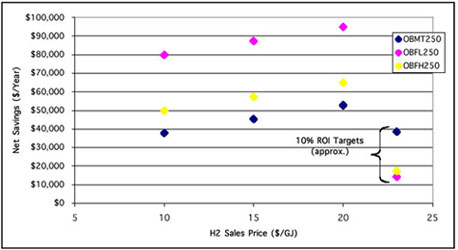

The second figure shows the the results for a 250-kW fuel cell H2E-Station at an office

building setting, along with approximate 10% ROI targets for each case (based on the

installed capital costs of each fuel cell/reformer/H2 storage and dispensing system). Note

that even with the medium-term case it appears that the ROI target could be met or

exceeded with a range of H2 sales prices. It would seem that in the energy market

conditions that prevail in certain parts of California such as the South Coast, fuel cells

with the assumed capital and operating costs can be cost-effective, and H2E-Stations

based on these relatively large fuel cells at office buildings could prove to be attractive.

This result shows that much of the economic benefit of H2E-Stations may be their ability to

displace relatively costly (at least in California) purchases of grid power, thereby

effectively cross-subsidizing hydrogen sales in early FCV market development scenarios.

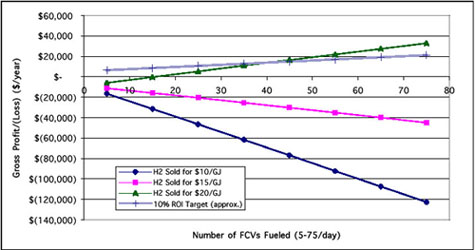

Finally, the third figure shows that a 10% simple ROI target can be met with the service

station type of H2E-Station, but only with relatively high hydrogen sales prices of about

$20 per GJ and only with about 50 or more vehicles per day refueled. At lower hydrogen

sales prices of $10-15/GJ, the economics of this type of station do not look attractive,

even with significant numbers of vehicles refueled. However, with lower natural gas

prices than the $6/GJ assumed in this "future high cost case," this picture would change

somewhat, with hydrogen sales prices of $15/GJ potentially becoming profitable for large

numbers of vehicles per day supported.

Project Overview

The Daimler-Chrysler NECAR4 Hydrogen Fuel Cell Vehicle

The PlugPower 7000 Residential Fuel Cell System

CETEEM Description

Project Goals and Sample Results

FCVs Used as DG vs. Stationary PEM Fuel Cells at Medium CA Office Building Setting

FCVs Used as DG vs. Stationary PEM Fuel Cells at CA Residential Setting

Note: LF = load following; NM = net metering.

Estimated Annual Costs of H2E-Stations with 25 and 40 kW Fuel Cell and 5-15 FCVs

Refueled per Day, Compared with Costs of Dedicated H2 Stations (H2 price of $10/GJ)

Estimated Savings from Office Building (OB) H2E-Stations with 250-kW Fuel Cell and 10

FCVs/Days Refueled for 264 Days/Year, with Medium-Term (MT), Future-Low (FL), and Future-

High (FH) Cost Cases, and Approximate 10% ROI Targets

Estimated Profit/Loss from H2E-Service Station with 40 kW Fuel Cell, 5 to 75 FCVs

Refueled per Day, and Future High Costs (w/approx. 10% ROI target)

CETEEM and V2G Publications Available and Forthcoming

References